Innovation and Precision in Plastics

Discover our high-quality services covering the entire production cycle. From mold making, through the injection molding process, to supplementary processing, we are the ideal partner to turn your ideas into tangible realities.

Our Services

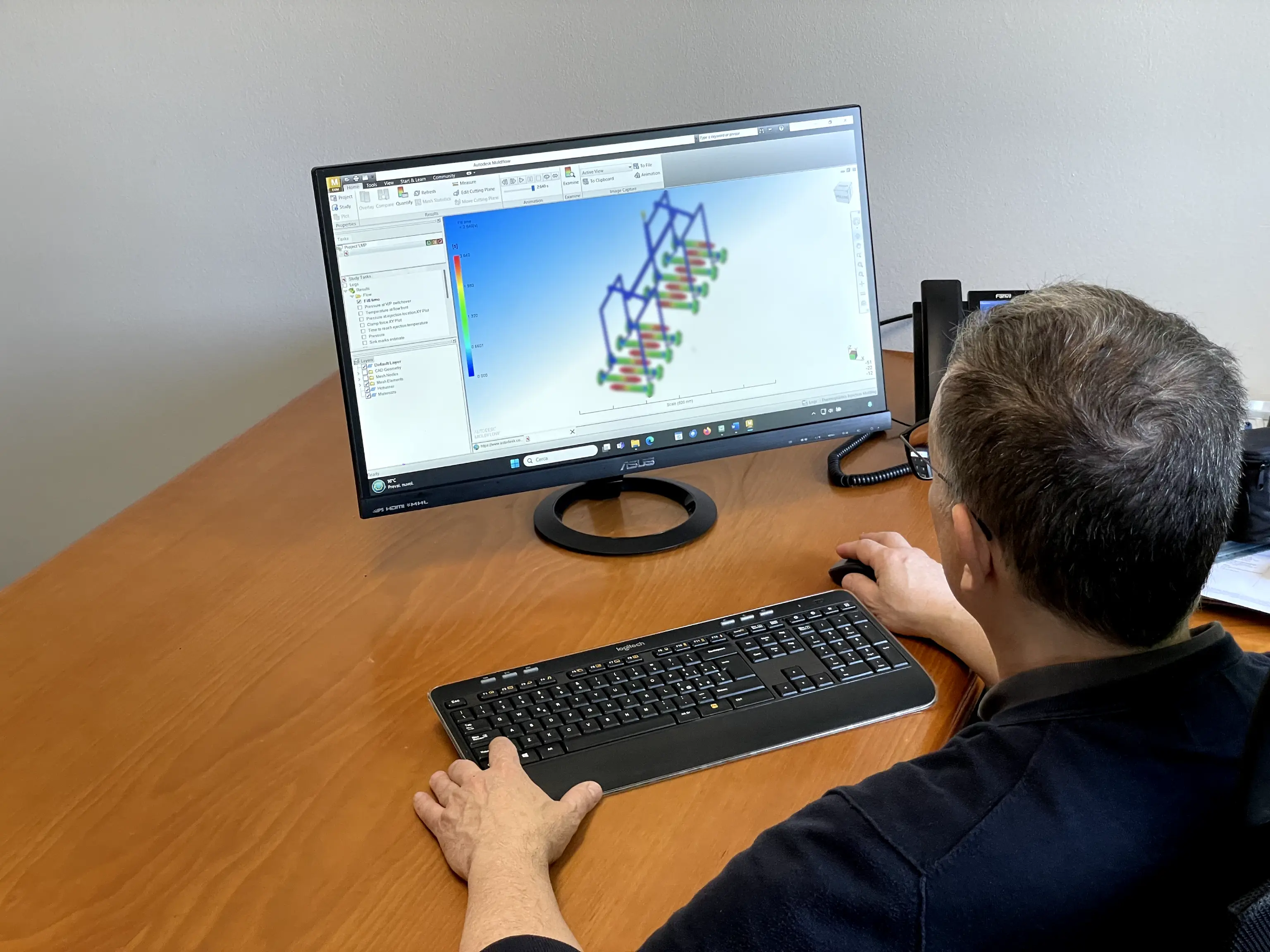

Mold Making

Mold Making

Plastic mold design is a crucial step in the production process. LMP offers a comprehensive service in collaboration with trusted and certified mold makers. Thanks to long-established partnerships, we are able to meet both large-scale and custom projects. Ongoing interaction with the customer is essential to identify specific needs and offer innovative solutions.

Choice of material

In the plastics molding process, selecting the right material is a critical step. With long experience in the industry, we fully understand this importance. Through prior consultation, our team identifies the optimal material for each project.

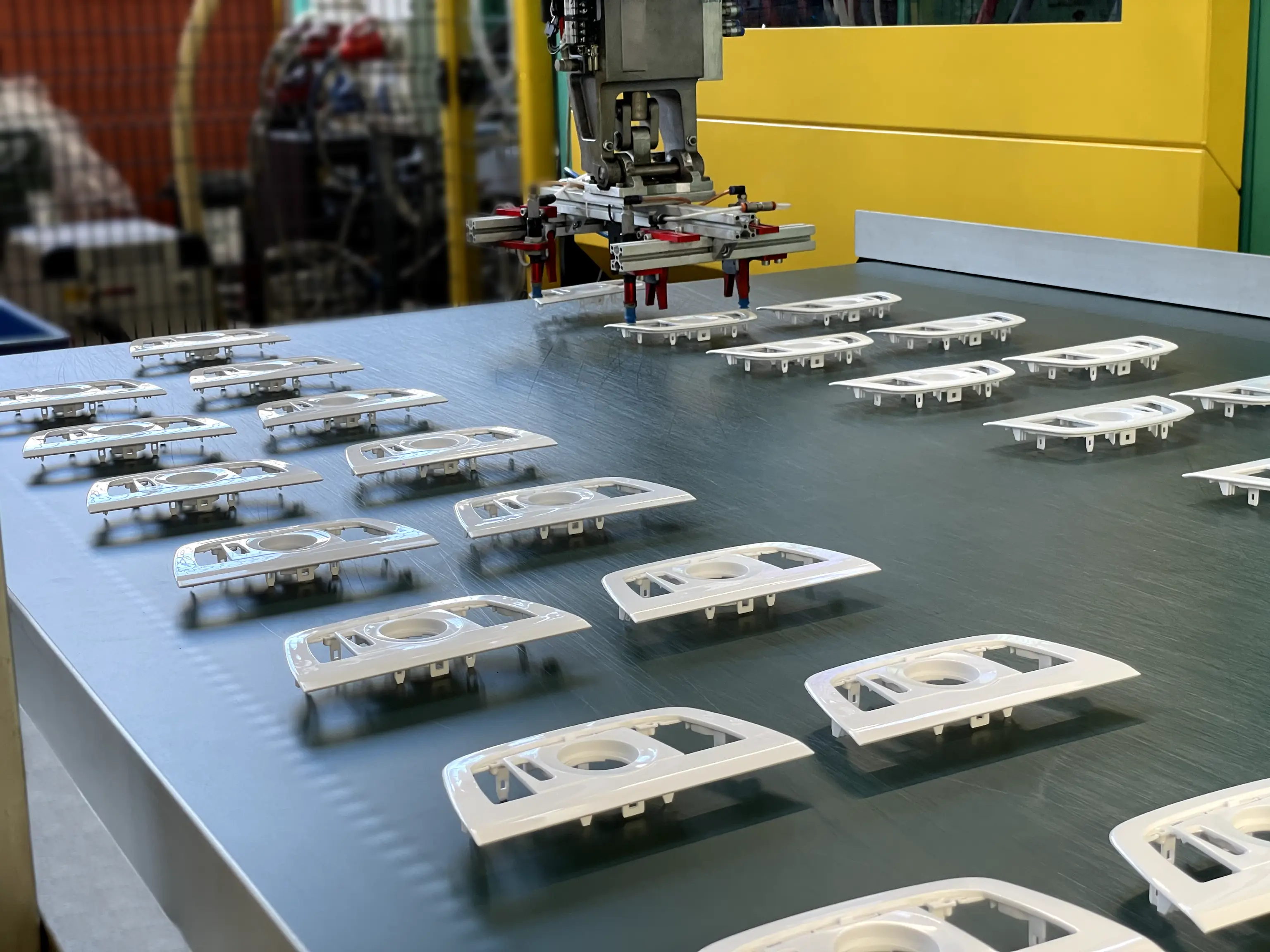

Injection Molding

Large machine fleet

At LMP we have 20 state-of-the-art presses. With capacities ranging from 500 KN to 5500 KN, we are ready to mold a wide range of parts, ranging from as small as 1 g up to 1.6 kg. This diverse tonnage range allows us to ensure quality and efficiency in every single part we produce.

Co-molding

Using the co-molding technique, inserts (typically of metal, brass or aluminum) are precisely positioned in the molding cavity, where thermoplastic material is molded around them. The result is a robust plastic component with a perfectly encapsulated insert.

Gas Assisted Injection Moulding

In GAIM (Gas Assisted Injection Molding), an inert gas is introduced inside the plastic material, which compacts on the walls of the mold. This process enables the production of lightweight and strong articles.

Bi-component with Babyplast

In two-component molding with Babyplast, two different plastic materials are injected into the mold, creating products with combined properties. This process allows unique characteristics, such as different hardnesses or colors, to be achieved in a single operation.

Complementary Processing

- Assembly

- Our assembly service guarantees the highest precision and attention to detail, ensuring high-quality finished products.

- Painting

- Painting of plastics, offers homogeneous and durable finishes that can be customized according to different design and functional requirements.

- Pad Printing

- Pad printing is ideal for decorating and marking irregular or curved surfaces, resulting in crisp, durable prints perfect for reproducing intricate details and vivid colors.

- Screen Printing

- Screen printing ensures color accuracy and vividness, creating unique visual effects.

- Chrome Plating

- Chrome plating gives products a sophisticated, reflective, and durable appearance, ideal for designer and high-end products.